NMB High Efficiency

NMB High Efficiency

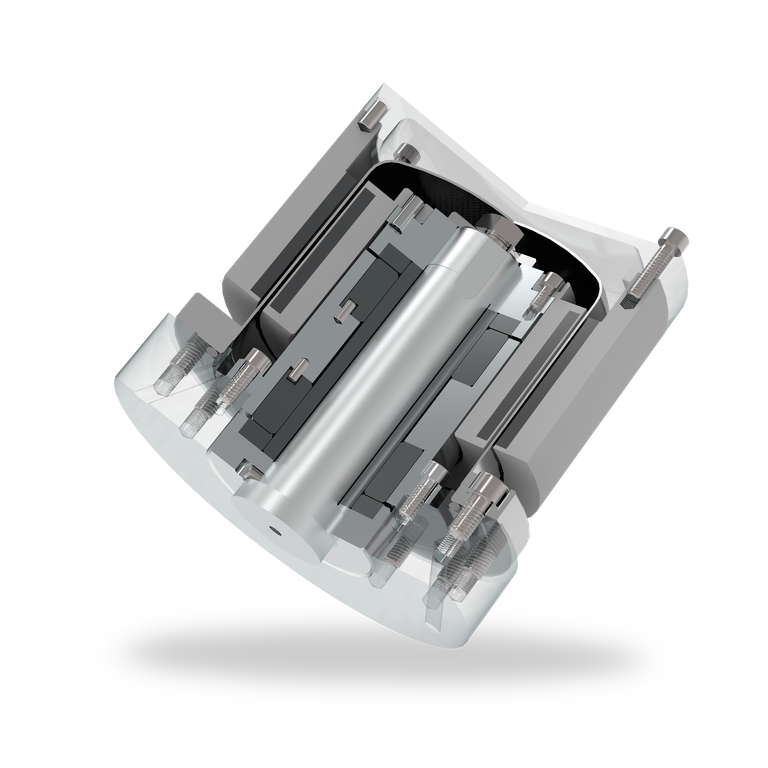

| Item | Description |

| 1.1 | Inner rotor |

| 1.2 | Outer rotor |

| 1.3 | Can |

NMB High Efficiency

Features

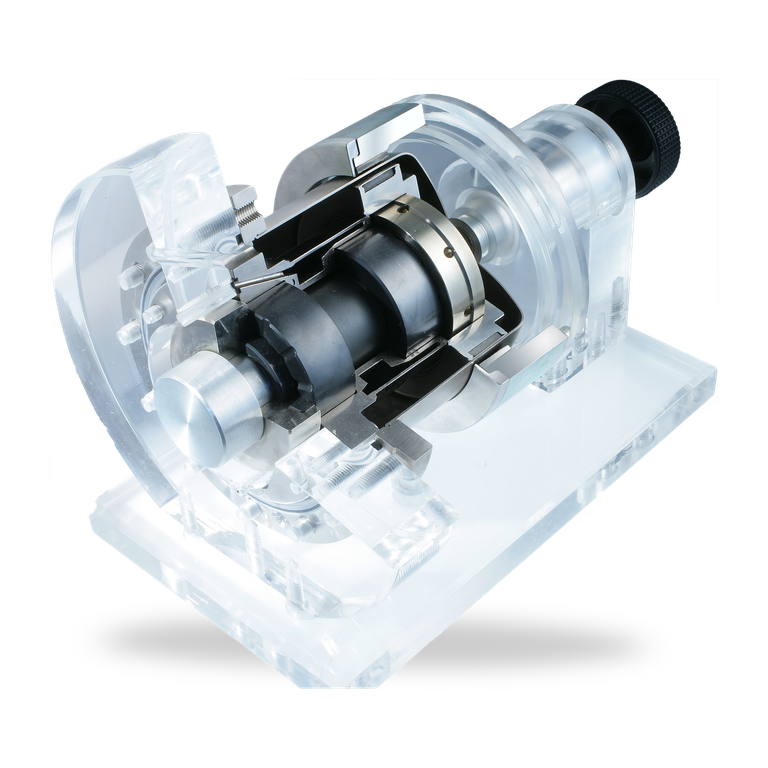

The NMB series is used successful in many applications worldwide. The can is made from PTFE-seal insulated rings and a slotted outer can, what reduces EC-losses to a minimum. They are designed for increased safety and energy savings. Thus they can handle large motor torques, high speed and high pressure.

Advantages

- Magnetic coupling for applications acc. to API 685 (similar to API 610)

- Hermetically sealed

- No contact of torque transmitting elements

- No maintenance necessary

- High efficiency can (Insulated rings and slotted outer can) for lowest eddy current losses (approx. 2 % of motor power)

- Increased safety and energy savings compared to solid Hastelloy® cans

- Sliding bearing optional

Materials

Magnets: Samarium cobalt (MA3),

Neodymium iron boron (MA8)

Metal parts: CrNiMo-Steel 1.4401/1.4436,

PTFE Polytetrafluorethylen (T)

Neodymium iron boron (MA8)

Metal parts: CrNiMo-Steel 1.4401/1.4436,

PTFE Polytetrafluorethylen (T)

Standards and approvals

- API 685

- Compliant to TA Luft (German Clean Air Act)

Recommended applications

- Chemical industry

- Oil and gas industry

- Refining technology

- Pharmaceutical industry

- Food processing industry

- Centrifugal pumps

- Gear pumps

- Top drive mixers/agitators

- Fans

- Blowers

- Autoclaves

- EagleBurgmann RoTechBooster

Functional description

The power transmission occurs contact-free through magnets from the drive shaft to the product wetted output shaft. Between the two rotating parts is the can which is bolted to the container.

Notes

Different variants are available to meet specific requirements:

- Version with integrated sliding bearing

- Dry running roller bearing

- High temperature variant

Similar products

eMAK

Magnetic couplings (MAK) are a hermetic, low-maintenance sealing solution for pumps, agitators, and aerators. Dangerous or precious media remains isolated in the closed system circuit. In turn, nothing penetrates to contaminate the medium.

- For standard applications up to 25 bar

- Available from stock

- Single-walled can

- Product-lubricated sliding bearing included (optional)

- High performing

- Energy efficient

- Highly reliable and maintenance-free

MAK66

Magnetic couplings (MAK) are a hermetic sealing solution for pumps and agitators. Dangerous or precious media remains isolated in the closed system circuit.

MAK685

Magnetic couplings (MAK) are a hermetic sealing solution for pumps and agitators. Dangerous or precious media remain isolated in the closed system circuit.